Martin Catalog QD Bushing J 1-3/4"

- group name

- J Bushing

- Min Order

- 20 piece

- model

- Martin Catalog QD Bushing J 1-3/4"

- Delivery clauses under the trade mode

- FOB, CIF

- Acceptable payment methods

- T/T

- update time

- Sun, 16 Jul 2017 11:30:30 GMT

Paramtents

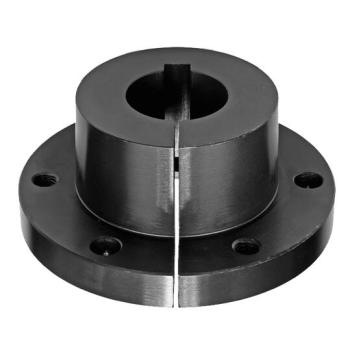

Product QD Bushing J 1-3/4"

Material steel

Catalog Martin

Bore 1-3/4"

Bolt Circle 6.250

Surface Treatment Blackoxided

Packging & Delivery

-

Min Order20 piece

Briefing

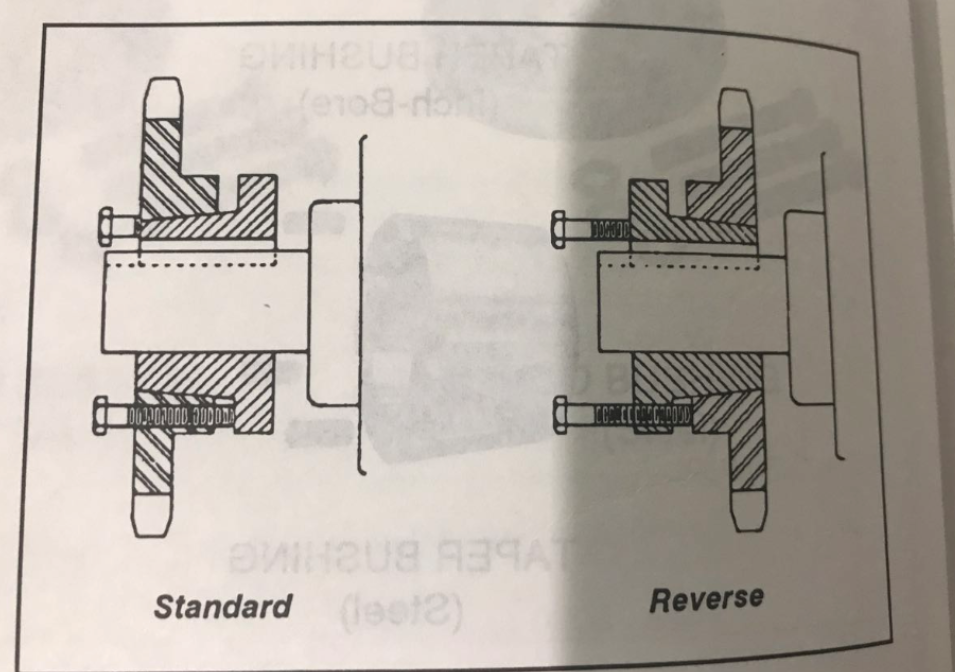

QD (quick detachable) bushings are designed for conventional mounting or reverse mounting. These bushings with a hub

Detailed

Martin Catalog QD Bushing J 1-3/4"

Martin Catalog QD Bushing J 1-3/4"

The taper-bored “QD” sprocket easily fits over the tapered hub and tightening of the cap screws produces a tight press fit on the shaft. The sprocket part is easily removed from the hub by using the pull-up bolts as jack screws in the holes tapped in the rim of the sprocket.

Zhijiang Sprocket factory has been making all kinds of Martin Catalog QD Bushing and sprockets for American customers more than 20years, material including steel C1045, SUS304, Casting.

If you need products details information, please contact us.

Product Specifications

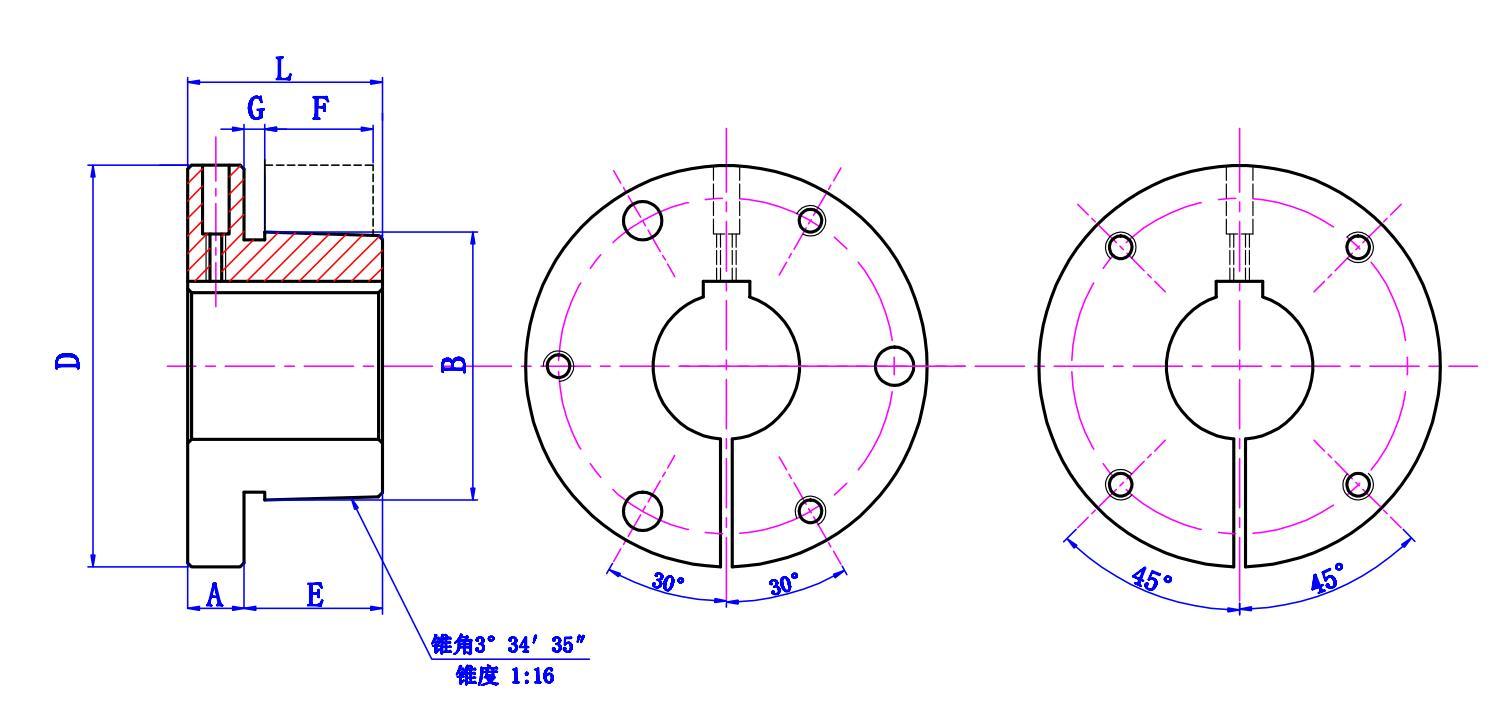

Bushing | J |

Weight |

18.00Lbs |

Material | Steel |

Bore |

1-3/4" |

A | 1.000" |

B |

5.148" |

D | 7.250" |

E |

3.500" |

F | 3.188" |

G |

0.188" |

L | 4.500" |

Keyway |

STD |

SetScrews | 5/8-11 |

CapScrews |

3-5/8X4-1/2 |

Installation

1. Be sure the tapered cone surfaces of the busing and the inside of the sprocket hub are clean.

2. Place bushing in sprocket, sheave, pulley or other QD parts.

3. Place cap screws and lock washers loosely in pulling holes. Bushing remains fully expanded to assure sliding fit on shaft.

4. With key on shaft, slide sprocket to desired position on shaft. Be sure heads of cap screws are on outside.

5. Align sprocket. Tighten screws alternately and progressively-until they are pulled up tight. To increase leverage, use wrench or length of pipe. Do not allow sprocket to be drawn in contact with flange of bushing; there should be a gap from 1/8” to 1/4”

Caution:

When mounting screws, apply pressure by hand only. If extreme tightening forces are applied, bursting pressures will be created in the sprocket hub. There should be a gap of 1/8” to 1/4” between the face of the sprocket hub and the flange of the QD bushing. The gap must not be closed. If the gap is closed under normal tightening, the shaft is seriously undersized.

Remove

Removal

1. Loosen and remove cap screws

2. Insert cap screws in tapped removal holes;

3. Tighten inserted screws until sprocket is loose on shaft;

4. Remove sprocket from shfat

Contact Information

Contact: Jimmy

Mail: info..........com/jimmy..........com

what app:+86 13588027172

Mobil: +86 13588027172

wechat:zjsprocket

Facebook: smartbhz..........com